Nice those will kick butt when the sandeels are around what did you make them from.

Cranky Old Bassturd.

They look great. whats the weight without the tails?

Your own idea or did you model it after something?

And.....whats it swim like?

White Water Monty 2.00 (WWM)

Future Long Islander (ASAP)

It’s mine own design I guess. The blue is 1 ½ oz and the green is 1 ¾. Made with 5/8 oak dowel and wired threw. They swim like a ava , but there waited in the back so you can keep them up top on a fast retrieve.

They look great. I bet they will be killer on the bass.

Madcaster, your first attempt at making plugs? Holy crap, they look good.

Good choice of the oak. They will be heavier and may sink a little more. Did you put any weights in them? I'm guessing they were hand machined and sanded. Speedy tells me oak is tough to work with because it's tough on the lathe tools.

Real nice work.

As an aside, if you or anyone else need oak stock in block form (12-18" stock, most pieces are at least 8"x8" in diameter and have been drying for 3 months now...let me know. We have more wood than we can use, and I put the oak aside (some heartwood pieces) in case someone wanted them.

dude that is awesome to the maxxx!!! how did u make the fins on top, i wud rlly like to kno. and if u need some body to test the things hit me up!!!!

They resemble a tallywhacker but on a smaller scale. Wicked.

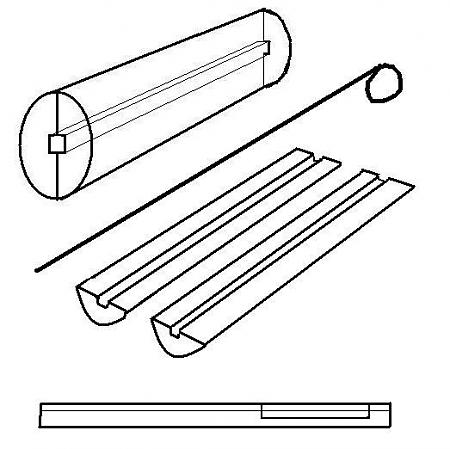

must have been a PITA to drill the thru wire on something that thin.

Cranky Old Bassturd.

2 pcs. got ya

Cranky Old Bassturd.

Elmer’s water proof glue. The glue will seal the grove. I place a larger wire in the grove before glue up. This allows you to twist it a few time while the glue is drying .This will allow you to pull the wire out, leaving a tube used to wire up the plug

Before glue up, the rear of the plug can be hollowed out to create a chamber for lead to be poured in later.